Anodised aluminium poles

Anodised aluminium poles for street/park lighting

Anodised aluminium poles

The anodised aluminium poles have a particularly good aesthetic appearance and a distinctive design that attracts attention. The production of anodised aluminium is very responsible and takes up to 12 hours, with the aluminium being dipped into different anodising baths. Depending on which different baths the aluminium is dipped into, different colours are produced.

Safe anodised aluminium poles

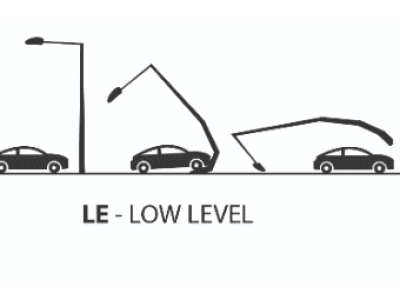

Road lighting ensures good visibility. This reduces the possibility of accidents. However, if an accident does occur, the type of bollards installed and whether they are safe are very important. Lighting poles shall be such as to minimise the effects of an accident. Poles must meet certain safety standards. This is described in the European standard EN-12767:2007.

To illuminate the streets, parks, highways, motorways and other areas of cities and towns.

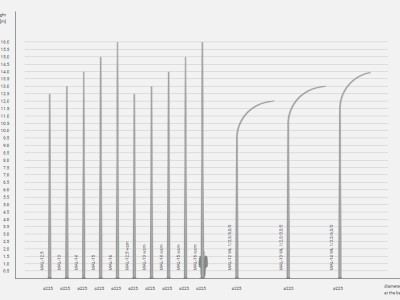

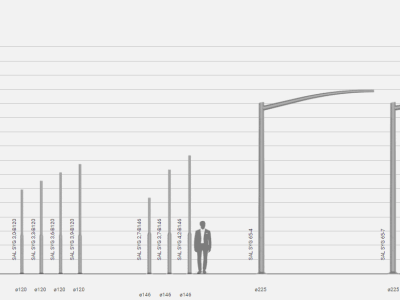

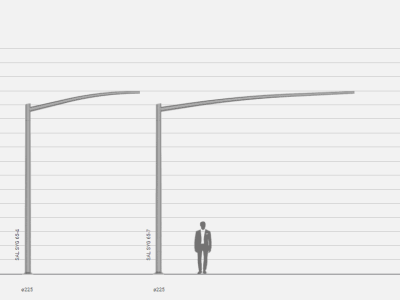

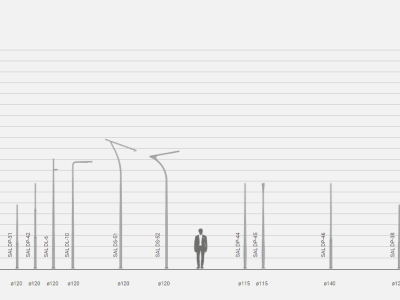

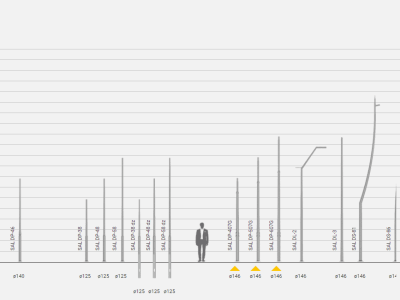

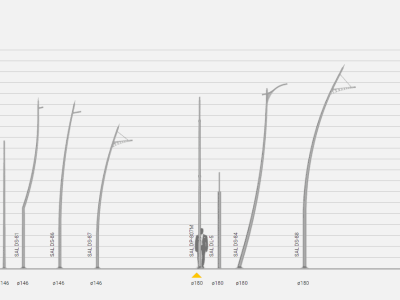

The height of the supports can vary from 2 metres to 12 metres.

Depending on the location of the support, and the contamination of the environment, anodised aluminium supports are subject to contamination. The supports are exposed to environmental pollution or fine mechanical particles (sand and chemicals in winter). These contaminations do not affect the technical parameters of the product, but do spoil the aesthetic appearance.

We therefore recommend periodic cleaning of the supports, which does not change the aesthetic appearance of the supports.

Cleaning of anodised aluminium poles

- First, wash the dirty surface with warm water;

- Drying;

- Clean the support surface with a neutral cleaning agent, e.g. COSMOFEN 60, COSMOKLAR COLOR or REYNATOR 718;

- Do not clean the supports with harsh instruments;

Our solutions include:

- Very high quality;

- Original and modern design;

- High corrosion resistance;

- 10 anodising colours to choose from

- Environmentally friendly.